Developed in-house and polished over sixteen years across four generations of invention, our core material is based on centrifugal drawing technology. With an annual manufacturing capacity of 36,000 tons, this ultra-fine glass fiber is ecologically benign and finds extensive application in appliances, building, and other sectors. Super Tech is leading the industry thanks in great part to our sophisticated manufacturing lines and special technical barriers.

With low thermal conductivity (effectively lowering edge heat transfer), great barrier qualities, and long product lifetime, Super Tech's self-developed nano barrier films offer remarkable performance. Apart from vacuum insulation panels for the home appliance sector, these films find use in food, packaging, cosmetics, pharmaceuticals, electronics, and building sectors. The annual capacity for production is nearly 100,000,000 m².

At Super Tech, we make significant investments in R&D to advance vacuum insulation and barrier technology. Our R&D department guarantees that our goods stay front and foremost in the sector by concentrating on seven core research areas.

The ST-Q helium permeability tester is designed for testing the gas barrier performance of ultra-high barrier films. It offers significantly lower detection limits compared to existing permeability testers, making it ideal for assessing VIP insulation materials, electronic packaging films, ultra-high barrier films, and composite films.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

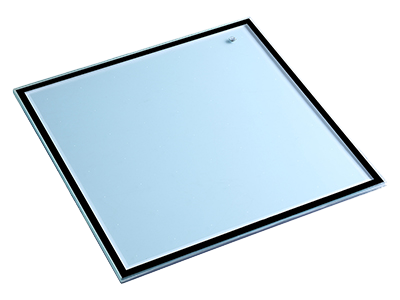

Designed to maximize the benefits of vacuum insulation by combining advanced materials and cutting-edge manufacturing techniques.

Multi-use passive cooled boxes of 2-8°C with up to 48-72 hours retention with optional remote monitoring capability.

Solve the problem of high recovery cost and difficult recovery.

Large capacity, easy assembly and disassembly, folding and recycling