Super Tech has actively pursued low carbon emissions with positive outcomes. In its manufacturing process, the corporation mostly runs on natural gas and electricity, therefore optimizing resource usage and energy-efficiency. Among the measures are the creation of new carbon-reducing goods, carbon-reducing technology in manufacture, and clean energy sources. The business has switched to rooftop photovoltaic panels to replace conventional electricity, therefore lowering carbon dioxide emissions.

Based on the vacuum insulation principle, the company's main product, the Vacuum Insulation Panel (VIP), is a high-efficiency insulating material that essentially lowers energy consumption in home appliances, cold chain logistics, construction, and other sectors, so helping to contribute to worldwide energy savings and carbon reduction. The corporation created a VIP using a metal material as an external barrier layer over the reporting period. This novel product can be utilized for insulation in pipe transportation, ovens, boilers, and new energy batteries according to internal tests showing good insulation performance in high and low-temperature areas.

Furthermore in development by the company is vacuum glass, with outstanding anti-frost, anti-condensation, light transmission, and insulation. Mass-produced, it will be a key energy-saving component for modern agriculture, buildings, rail transportation, and appliances.

The company generates no industrial wastewater. Before being dumped into the municipal sewage system, domestic wastewater in the company's living quarters is cleaned using septic tanks in line with the "Comprehensive Wastewater Discharge Standards" (GB8978-96).

Super Tech keeps improving its EHS initiatives to guarantee manufacturing environmental protection and safety. For every division of the corporation, the EHS system has been developed in great detail. The company and its primary subsidiary, FUJAN SUPERTECH COLD CHAIN TECHNOLOGY CO., LTD, have both been certified for their Occupational Health and Safety Management Systems, Environmental Management, and Quality Management.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

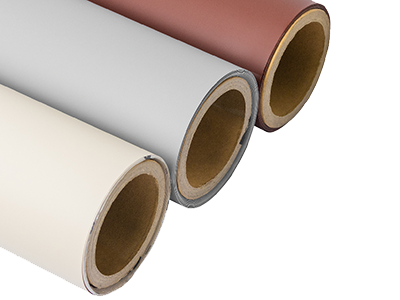

Designed to replicate the look and feel of real leather, Skin-Feel Film is a flexible and premium material Made from PU synthetic leather, PVC imitation leather, or PU real leather, it offers furniture, home décor, and full-house customizing an ultra-realistic texture and aesthetic ideal.

Designed for exceptional barrier protection, Aluminum-Plastic Composite Film (V4) is a high-performance composite.

Designed using modern nanotechnology, nano barrier films are high-performance films. Excellent barrier qualities from its nano-scale porous structure help to stop particles, microbes, chemicals, and toxins.

Excellent substitute for conventional aluminum foil in VIP (Vacuum Insulation Panel) uses, the Aluminum-Free Composite Film (V5) blends advanced vacuum metallized PET with EVAL to offer exceptional water and oxygen barrier properties.