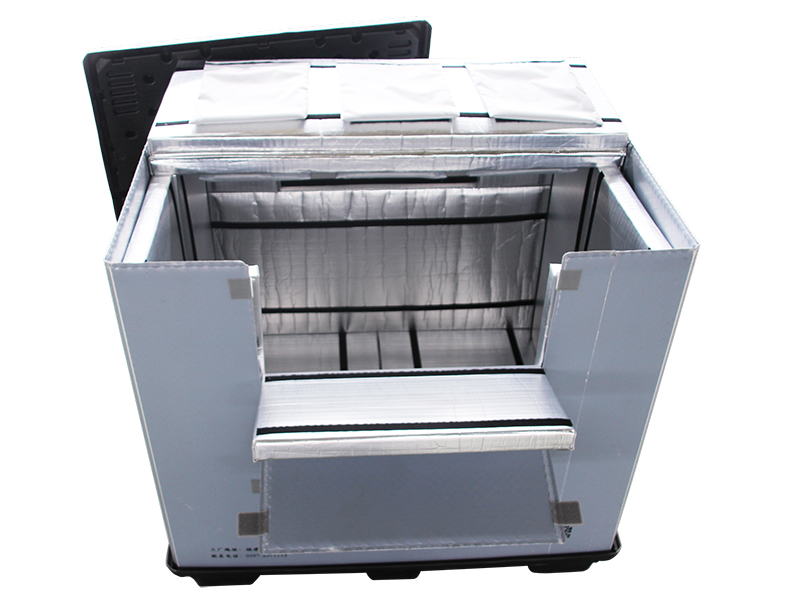

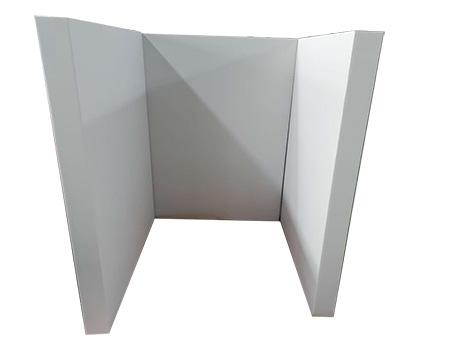

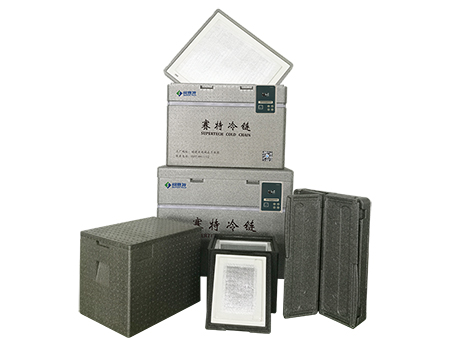

Our integrated vacuum insulated box can target customers of varying needs in the cold chain transportation of medicine, fresh health product, food, etc. Various accessories is also available to suit different applications, such as insulating material, phase change material (PCM) cold pack, temperature indicator, Bluetooth printer, non-woven cooler bag, insulated box liner and so on.

Such kind of vacuum insulated box can be applied to the recycling and reusing of medicine, fresh food and other types of food, largely making our life convenient.

It is a portable vacuum insulated box for the thermal insulation of medicine, fresh food and other types of food. Temperature and humidity record instrument is also a good option for you to check temperature and humidity.

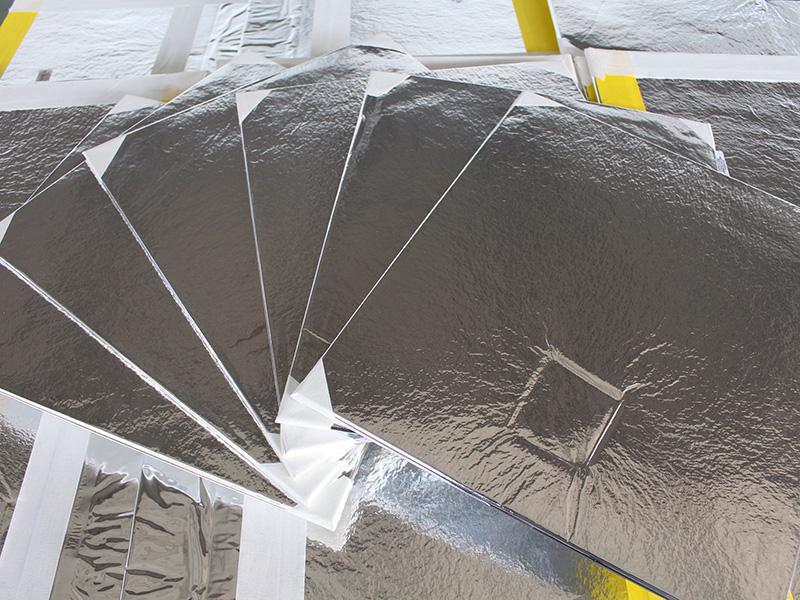

As the core material of vacuum insulated box, VIP has a very low thermal conductivity, which can effectively reduce heat transfer from external surface to internal volume of vacuum insulated box.

In order to meet different application and cost requirements of customers, we have a stock of VIPs panel in various designs and specifications for your selection.

Phase change material (PCM) cold pack is able to enhance the thermal management of the vacuum insulated box for a low temperature cooling system during its discharging cycle.

The outer shell of it is food grade HDPE hard plastic that is safe, odorless and green. And the PCM-filled HDPE filled with 90% of its volume, can be frozen without any deformation.

The phase transition temperature range of the PCM cold pack: 20℃, 15℃, 5℃, 0℃, -20℃.

According to the customer requirements, we have developed medical vacuum insulated box with no cooling energy discharge.

The cooling energy discharge in advance of phase change material (PCM) cold pack can protect the products such as vaccine, medicine, etc. from excessive cold in the transportation at 2-8℃. However, to control the time of the cooling energy discharge presents difficulties because too long time will affect the thermal duration time on the one hand and on the other hand if the cooling energy discharge occurs at 2-8℃, 6 hours will be wasted and operators also need professional training.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

Designed to maximize the benefits of vacuum insulation by combining advanced materials and cutting-edge manufacturing techniques.

Multi-use passive cooled boxes of 2-8°C with up to 48-72 hours retention with optional remote monitoring capability.