Vacuum insulation panel based on fiberglass core material, a new energy-efficient insulation material following the adiabatic principle for insulation, consists of three major parts: fiberglass core materials, getter materials/desiccants and high barrier laminates.

Vacuum insulation panel based on fumed silica core material consists of two major parts: fumed silica core material and high barrier laminates. As a special composite made of core materials and protective layers, it is integrated with the superiority of vacuum insulation and micro-pore heat insulation, effectively stopping convective heat transfer to perfect thermal insulation.

Although vacuum insulation panel has a good insulating performance and barrier property, we further have developed robust, durable polyurethane vacuum insulation panel (PU-VIP) for collision avoidance upgrading from vacuum insulation panel based on fiberglass core material combined with polyurethane foam (PU).

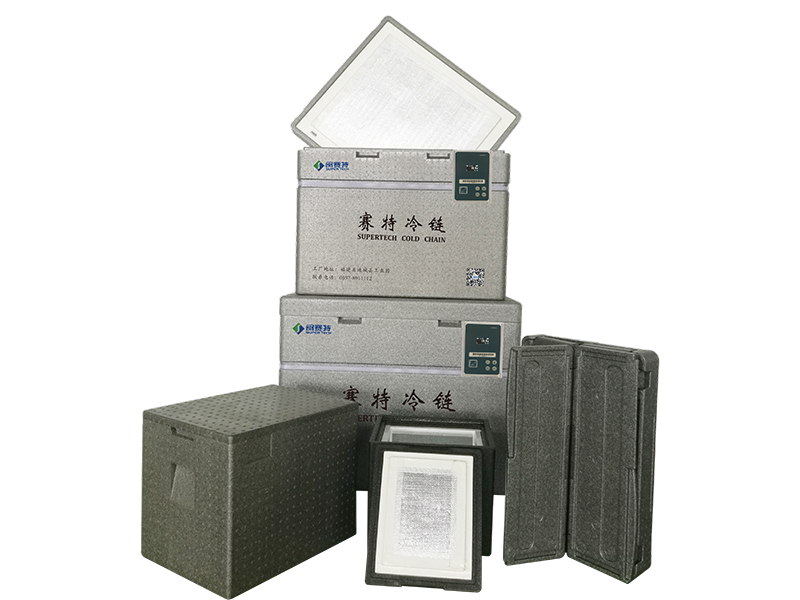

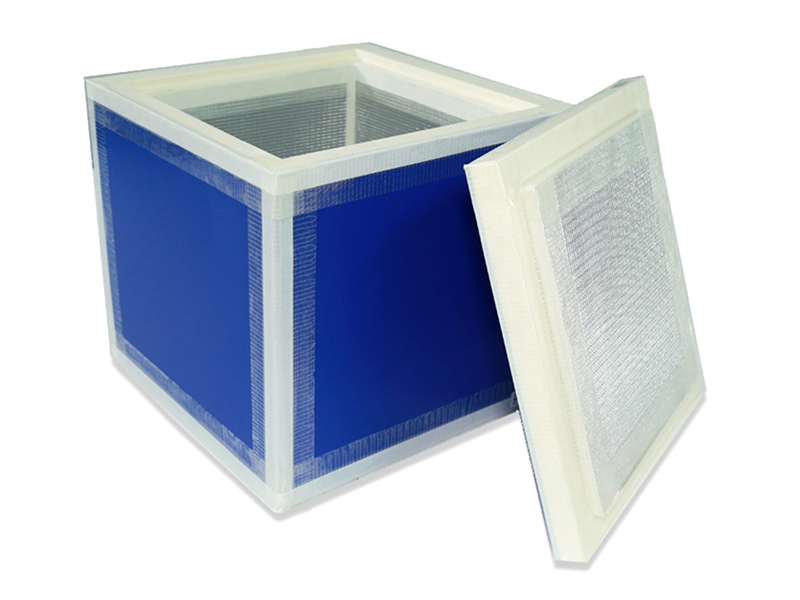

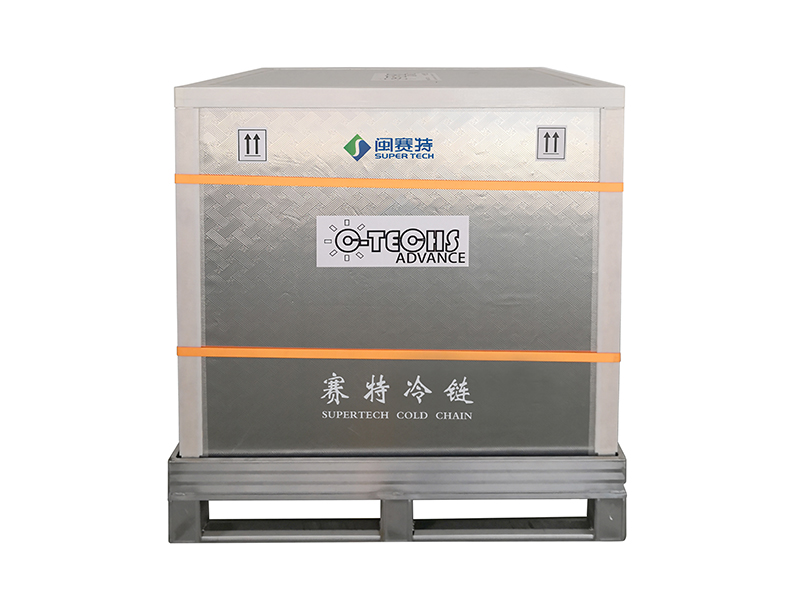

Our integrated vacuum insulated box can target customers of varying needs in the cold chain transportation of medicine, fresh health product, food, etc. Various accessories is also available to suit different applications, such as insulating material, phase change material (PCM) cold pack, temperature indicator, Bluetooth printer, non-woven cooler bag, insulated box liner and so on.

Designed to maximize the benefits of vacuum insulation by combining advanced materials and cutting-edge manufacturing techniques. Made of low-emissivity coated tempered glass, high-performance desiccants, and lead-free alloy flexible solder, VIG offers exceptional thermal insulation while staying transparent—a great fit for modern architecture and energy-efficient building systems.

Multi-use passive cooled boxes of 2-8°C with up to 48-72 hours retention with optional remote monitoring capability.

Portable heat preservation demand for storage and deliveries of pharmaceuticals, fresh and food, etc.

Cold chain transportation for pharmaceuticals, fresh, food, etc

Solve the problem of high recovery cost and difficult recovery.

Large capacity, easy assembly and disassembly, folding and recycling

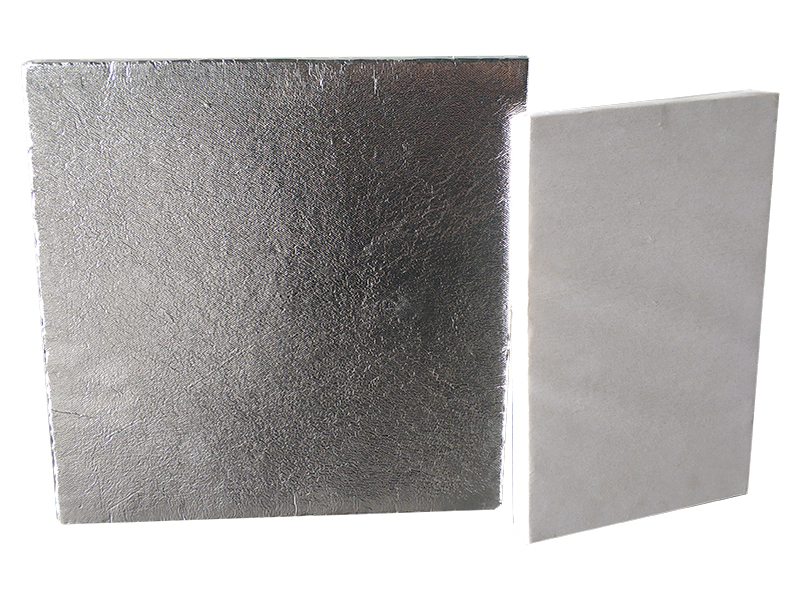

The quality of barrier material plays a key role in the service life of VIP. With the best barrier property, Al foil is widely used in barrier film for vacuum insulation panel. Moreover, there are many other kinds of barrier film, such as Al, EVOH, PVA, PA, MPET for the barrier function and LLDPE, CPP for heat sealing effect. As a compound of these above materials, Al foil barrier film has the extensive application in the market.

Supertech fiberglass mat consisted of a uniformly distributed, thin fiberglass mat has the minimum solid skeleton heat transfer. With high thermal insulation properties and excellent anticorrosion, it is a perfect material for vacuum insulation panel, oven and microwave oven.

A vacuum insulated panel (VIP) is a new form of thermal insulation following the adiabatic principle for insulation. As a special composite made of core materials and protective layers, it is integrated with the superiority of vacuum insulation and micro-pore heat insulation, effectively stopping convective heat transfer to perfect its thermal insulation. With a thermal conductivity of as low as 0.0015w/m.k to 0.0025 W/m. K, the thermal resistance of our vacuum insulation panel is ten times higher than those conventional insulation materials and even more. Compared with traditional PU insulation materials, vacuum insulation panel, both energy-saving and environment-friendly, contains no ODS (ozone depleting substances) in its process of manufacturing. It is also regarded as advanced high performance insulation material.

Vacuum insulated panel has been widely applied to various thermal insulation products such as refrigerators, freezers, refrigerated trucks, cold storages, insulated shipping containers, ice storage tanks, etc. Through increasing the degree-of-vacuum of vacuum insulated panel to the limit, these thermal insulation products have a high-performance insulation and energy saving effect. With the upgrading of insulation material, vacuum insulated panel has achieved a great development. It can halve the energy and electricity consumption with half-thickness. Today, in keeping with the trend of CFC-free thermal insulation products in the future development, vacuum insulated panel, featured with energy conservation and large volume in a thin design, has been widely applied to refrigerators.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

An extremely high thermal protectionis necessary in the transportation of medicine, fresh food, etc., with people’s highly increasing expectations on cold chain transportation.

Based on refrigerator’s energy consumption and its actual storage space, various applicable products are available for our customers according to your different needs.

With the increasing demand for thermal insulation layer in modern logistics system, there is a high rise trend on more useful volume and lighter packaging for saving transportation cost.