An extremely high thermal protectionis necessary in the transportation of medicine, fresh food, etc., with people’s highly increasing expectations on cold chain transportation. Integrated with phase change material (PCM) cold pack, our vacuum insulation box consists of vacuum insulation panel and traditional insulation materials (PU, EPS, EPP, etc.) for different temperature and energy efficiency requirements, maintaining the solid temperature performance in transportation.

With good sealing property, our vacuum insulation box not only allows for smaller volumetric size of transportation with low costs but also offers long lasting temperature control and good air quality inside. So far, it has been applied to the storage and transportation of vaccine, pharmaceutical, insulin, HAS, clinical specimen, ice cream, fresh food.

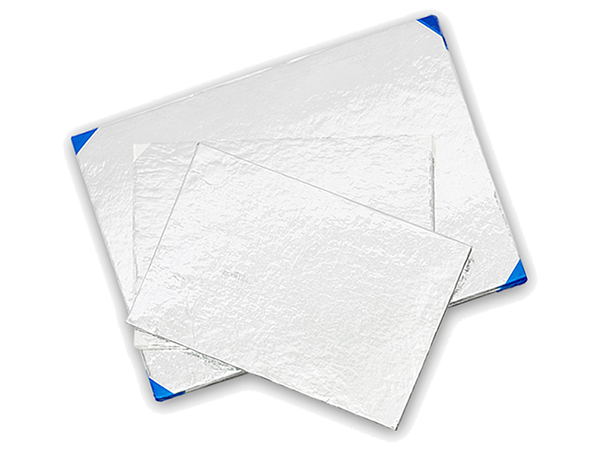

Vacuum insulation panel based on fiberglass core material, a new energy-efficient insulation material following the adiabatic principle for insulation, consists of three major parts: fiberglass core materials, getter materials/desiccants and high barrier laminates.

Vacuum insulation panel based on fumed silica core material consists of two major parts: fumed silica core material and high barrier laminates.

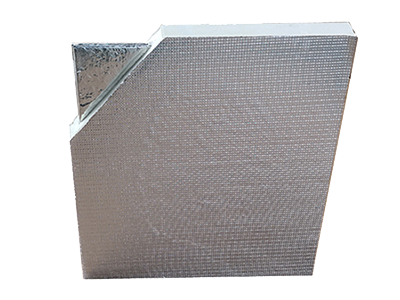

Although vacuum insulation panel has a good insulating performance and barrier property, we further have developed robust, durable polyurethane vacuum insulation panel (PU-VIP) for collision avoidance upgrading from vacuum insulation panel based on fiberglass core material combined with polyurethane foam (PU).

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

Based on refrigerator’s energy consumption and its actual storage space, various applicable products are available for our customers according to your different needs.

With the increasing demand for thermal insulation layer in modern logistics system, there is a high rise trend on more useful volume and lighter packaging for saving transportation cost.