As the major raw material, fiberglass core material involves two processing methods: dry processing method and wet compression molding. Fiberglass core material, with 6-12 micron fiber diameter in compliance with EU standards of minimum fiber diameter more than 6μm, imposes strictly controls on the baking temperature and time of core material to ensure its quality. There are 12 core material production lines with the daily capacity of 120 tons. We can offer our customers timely and adequate service based on our own core materials.

VIP needs to adopt a high barrier packaging bag with low thermal conductivity, high barrier property and long service time.

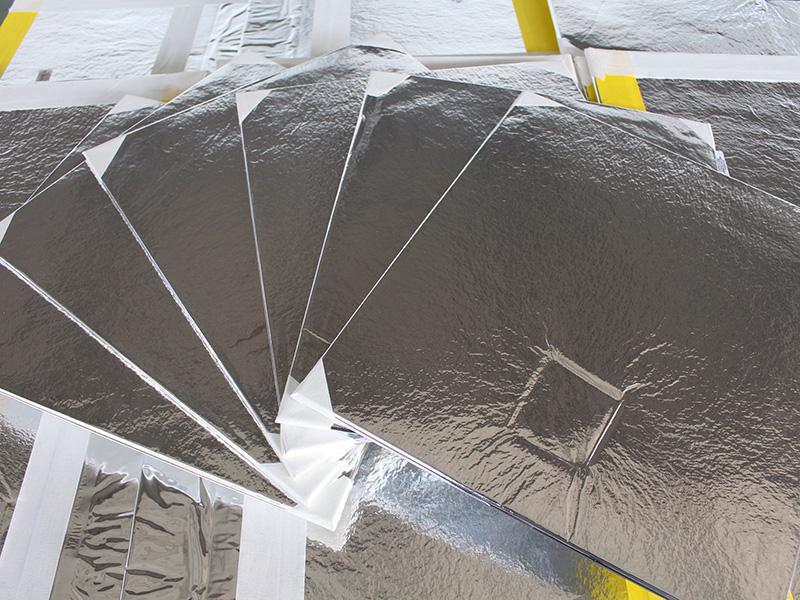

According to this unique characteristic, we have conducted our own R&D and carried out large-scale production of barrier films with high vapor and gas barrier properties including foil barrier film, hybrid barrier film and non-foil barrier film respectively confirming to different energy efficiency index of different countries.

CaO desiccant and Barium-lithium alloy based getter material are our main products.

CaO desiccant is often used to absorb the vapor while Barium-lithium alloy based getter material can be applied to the adsorption of vapor and other residual gas (O2, N2, etc.) inside VIP. These two kinds of adsorbent materials has passed REACH and ROHSSGS testing from SGS and product safety test (fire test) to ensuring the long term stability of VIP.

There are 2 automatic vacuum packaging lines with 40 vacuum packaging machines in our factory. We start tight process control of vacuum packing to ensure the key performance parameters of vacuum insulation panel with the degree-of-vacuum (≤10-1Pa) and the vacuum evacuation time (>20mins).

We boast a team of well-trained and professional operators skilled in the folding process to allow the formation of VIP with folded edge construction.

We possess 40 rapid detection instruments to calculate the vacuum level of VIP in an effective way with the average testing time of 10s. Reliable detection results are achieved with NETZSCH from Germany and EKO from Japan, offering a 100% quality guarantee of our VIP before it leaves the factory.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

It is a portable vacuum insulated box for the thermal insulation of medicine, fresh food and other types of food.

As the core material of vacuum insulated box, VIP has a very low thermal conductivity, which can effectively reduce heat transfer from external surface to internal volume of vacuum insulated box.

Phase change material (PCM) cold pack is able to enhance the thermal management of the vacuum insulated box for a low temperature cooling system during its discharging cycle.

A high-tech electronic product combined with a precision high accuracy temperature sensor ICs; The same size as a USB and convenient to carry;