Barrier films are widely used in food packaging, medical applications, electronics, energy sectors, cosmetics and personal care products, agricultural preservation, and construction materials.

To select the appropriate barrier film, consider factors such as material, barrier performance, thickness and size, cost, sustainability, market reputation, customer reviews, and the specific application.

Barrier films help maintain product freshness and quality, prevent contamination and external factors, and provide better packaging aesthetics and display.

Injection molded insulation boxes offer excellent insulation performance, good corrosion resistance, high structural strength and impact resistance, low weight, effective sealing, and ease of cleaning.

These boxes are widely used in food, pharmaceuticals, agriculture, temperature-controlled logistics, laboratories, and research fields.

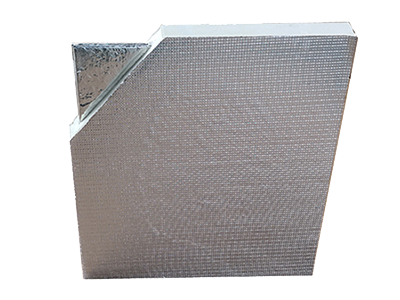

Vacuum insulation panels are suitable for industries such as metallurgy, chemicals, electronics, aerospace, automotive manufacturing, and construction.

Yes, vacuum insulation panels are a new material that reduces energy consumption by decreasing thermal conductivity. By creating a vacuum layer within the material, they reduce heat transfer and minimize energy loss.

Compared to traditional materials, vacuum insulation panels offer superior insulation performance, higher strength, and stability, making them suitable for various environmental conditions and providing longer-lasting results.

Yes, vacuum insulation panels have significant potential in building energy-saving, reducing energy consumption by over 30% and lowering the thermal conductivity of buildings by over 80%.

Preliminary tests show that SuperVIG vacuum glass can last over 25 years. With the independently developed alloy material welded to the glass under low temperatures, it ensures a vacuum leak rate of ≤ 10⁻¹² mbar·L/s, guaranteeing a quality lifespan of at least 25 years. Most products may exceed this usage period.

Vacuum glass has edge effects, and the area around the edge weld ribbon is not vacuumed, allowing some heat conduction. Therefore, to achieve significant frost and condensation prevention, SuperVIG vacuum glass should be used in conjunction with a frame.

Yes, vacuum glass provides sound-insulation benefits. The vacuum layer inside the SuperVIG glass effectively blocks the transmission of sound, creating a more comfortable living and working environment.

SuperVIG vacuum glass products are designed to operate below 100°C. The melting point of the welding ribbon in the finished product is approximately 250°C.

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

To provide extraordinary thermal conductivity and low rebound performance, the Glass Microfiber VIP blends a hot-pressed glass microfiber core with alkali-free fiberglass film.

Vacuum insulation panel based on fumed silica core material consists of two major parts: fumed silica core material and high barrier laminates.

Although vacuum insulation panel has a good insulating performance and barrier property, we further have developed robust, durable polyurethane vacuum insulation panel (PU-VIP) for collision avoidance upgrading from vacuum insulation panel based on fiberglass core material combined with polyurethane foam (PU).

Our integrated vacuum insulated box can target customers of varying needs in the cold chain transportation of medicine, fresh health product, food, etc.