Developed in-house and polished over sixteen years across four generations of invention, our core material is based on centrifugal drawing technology. With an annual manufacturing capacity of 36,000 tons, this ultra-fine glass fiber is ecologically benign and finds extensive application in appliances, building, and other sectors. Super Tech is leading the industry thanks in great part to our sophisticated manufacturing lines and special technical barriers.

First generation of vacuum insulating panels and core materials were developed. High-end home appliances made use of first-generation core materials, defining Super Tech's competitive edge.

Over 16 years, Super Tech has undergone four major breakthroughs in core material R&D and production line upgrades

First-generation wet-process core material launched (initial thermal conductivity < 4.0 mW/(m·K)).

Second-generation wet-process core material launched (initial thermal conductivity < 3.5 mW/(m·K)).

First dry-process core material launched (initial thermal conductivity < 2.5 mW/(m·K)).

Annual production capacity of 36,000 tons of ultra-fine fiberglass core material (initial thermal conductivity < 1.5 mW/(m·K)).

We customize vacuum insulation panels to meet your specific requirements. Please email us or give us a call to find more information.

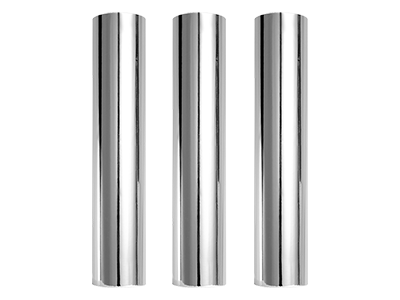

The quality of barrier material plays a key role in the service life of VIP. With the best barrier property, Al foil is widely used in barrier film for vacuum insulation panel.

Designed to offer best protection for flexible printed circuit boards (FPCs).

Made by carefully depositing a thin aluminum layer on the top of polyester film, Metalized PET Film (VMPET) is a high-performance composite material.

SiOx Barrier Film (PSI) is a transparent, high-barrier film that has remarkable qualities, such as resistance to moisture and oxygen.