Cases

This product has been discontinued and removed from our shelves.

| Case one | ||

|

Time | December 2018 |

| Place | Shanghai | |

| Project name | Medical vacuum insulated box with no cooling energy discharge | |

| Customer requirements | No cooling energy discharge | |

|

Solutions |

According to the customer requirements, we have developed medical vacuum insulated box with no cooling energy discharge. The cooling energy discharge in advance of phase change material (PCM) cold pack can protect the products such as vaccine, medicine, etc. from excessive cold in the transportation at 2-8℃. However, to control the time of the cooling energy discharge presents difficulties because too long time will affect the thermal duration time on the one hand and on the other hand if the cooling energy discharge occurs at 2-8℃, 6 hours will be wasted and operators also need professional training. |

| Case two | ||

|

Time | January 2019 |

| Place | America | |

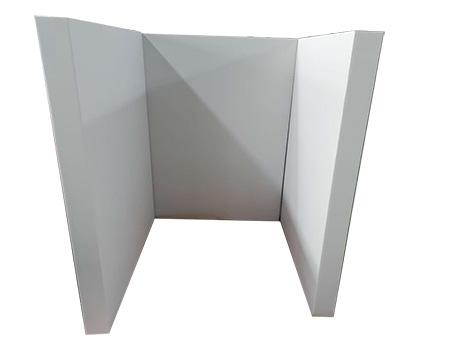

| Project name | Insulated pallet box | |

| Customer requirements | Detachable and cost effective | |

|

Features of VIP | VIP has a thermal conductivity of 1.5~2.5mW/m•K; EPS is used as the double-sided protective layers of VIP; |

| Solutions |

Such an assembled vacuum insulated pallet box is detachable enough for its exports to foreign markets in a cost effective way. With EPS as its double-sided protective layers, it is very light and easy to use. Each side of panel that is damaged can be replaced with a new one immediately. Assembled vacuum insulated pallet box can still be piled up separately in its recycling and storage, taking up less space for cutting operating costs. |

|

| Case three | |

| Time | March 2017 |

| Shanghai | Shanghai |

| Project name | Perforated plate vacuum insulated box for medical logistics |

| Customer requirements | The thermal duration time of 96 hours at 2~8℃; Impact resistance; |

| Solutions |

The structural material of perforated plate vacuum insulated box for medical logistics adopts PP perforated plate with edge and corner guards, the core insulating layer of which is VIP integrated with phase change material (PCM) cold pack, meeting the customer requirements of its thermal duration time. Besides, it is also convenient to carry with the matching non-woven cooler bag. |

| Case four | |

| Time | May 2017 |

| Place | Beijing |

| Project name | EPP + PU + VIP vacuum insulated box for medical logistics |

| Customer requirements | The thermal duration time of 72 hours at 2~8℃; |

| Solutions |

Integrated with phase change material (PCM) cold pack, EPP + PU + VIP vacuum insulated box adopts EPP as its structural material and PU-VIP its core insulating layer, meeting the customer requirements of its thermal duration time. |

| Case five | |

| Time | October 2016 |

| Place | Britain |

| Project name | PET+PU-VIP+PET vacuum insulated box for medical logistics |

| Customer requirements | The thermal duration time of 72 hours at 2~8℃; |

| Solutions |

Integrated with phase change material (PCM) cold pack, PET+PU-VIP+PET vacuum insulated box adopts PET as its structural material and PU-VIP its core insulating layer, meeting the customer requirements of its thermal duration time. It is also portable with the matching non-woven cooler bag. |

| Case six | |

| Time | April 2017 |

| Place | Australia |

| Project name | PP hollow sheet +PU+VIP vacuum insulated box for medical logistics |

| Customer requirements | The thermal duration time of 72 hours at 2~8℃; |

| Solutions |

Integrated with phase change material (PCM) cold pack, PP hollow sheet +PU+VIP vacuum insulated box adopts PP hollow sheet as its structural material and PU-VIP its core insulating layer, meeting the customer requirements of its thermal duration time. It is also portable with the matching non-woven cooler bag. |

-

- Vacuum Insulation Panel (VIPs) Based on Fiberglass Core Material

- Vacuum Insulation Panel (VIPs) Based on Fumed Silica Core Material

- Polyurethane Vacuum Insulation Panel (PU-VIPs)

- Vacuum Insulated Box, VIP Insulated Shipping Containers

- Vaccine Carrier Box

- Pharmaceutical Cooler Box

- Vaccine Insulated Pallet Shipper

- Barrier Film

- Fiberglass Mat

-

Add.: Liancheng Industrial Zone, Longyan City, Fujian Province

Contact Person: Caroline Lee

Email: caroline@supertech-vip.com

Mobile: +86-18650183889

Tel.: +86-592-6199938